Simplify the carton box packaging design

Tuesday, February 28, 2012

Basic functions of product packaging

a> Security functions

Falling into the product during transport, vibration, and should be protected from discomfort. Perishable foods such as fruits, you will need laminated rigid packaging such as containers should be protected. In addition, the product packaging will not be transferred, without a lot of static and dynamic load to the subject of handling and storage, must withstand. Assets, there is another if the package is needed, temperature protection, radiation, humidity, and from climatic conditions such as sun and rain is common.

2>load and transport functionsEasy management activities, lift, move, are determined, efficiently and safely, easy to modify, is the development of the transport package. Product packaging is an effective transportation, processing, and is one of the most important factors for and save. Loading and transport function of the request to the weight of the packaging of goods outside of the package and placed inside a convenience. On the other hand, power packed a close relationship, between the functions required for the installation of goods, carrying and transportation with security.

3> Sales & Marketing functionsWith the purpose of this function, the sales process becomes easier and more efficient. Product packaging has been designed to have a positive impact on purchase decisions of packaging and promotional materials attract the attention of potential buyers. Because they speak directly to consumers for packaging promotional material, which plays an important role in the delivery. This is a small role in the original package.

4>Storage function

They are stored in different locations and packaging materials, you must have the necessary container used for packaging products. The container must be stored in the warehouse.

In addition, the package contains a package of warranty service based on features and brand, to consumer protection and product liability. The product package there is a legal requirement be labeled expiration date, nature, composition, weight, number and, clearly, etc., but have played a role in a number of features for content protection, Perhaps the most important work, are considered in order to sell their goods in the market yet.

Monday, February 27, 2012

Sunday, February 26, 2012

The structure of carton packaging

When we choose the material for the carton box, next step would be applying to reasonable, scientific structural packaging design in order to keep the goods safe during transportation and storage.

In a number of packaging materials, paper and paperboard as a packaging material not only has a long history, but also accounts for a sizeable proportion. In this article I would like to take carton box packaging design as an example introduce the knowledges realted to carton box structural packaging.

According to the usages and the shapes, the paper packaging structure can be summarized as the following four aspects: the structure of carton packaging, the structure of paper bags and paper cups packing structure.

The structure of carton packaging can be divided into folding carton structural design and glued carton structural design.

Folding cartons with high efficiency, facilitate the sales and carrying, and it has low production costs, coupled with the use of folded stacked to save the packaging warehousing and transportation costs, etc., so folding carton has been widely adopted in the packaging industry.

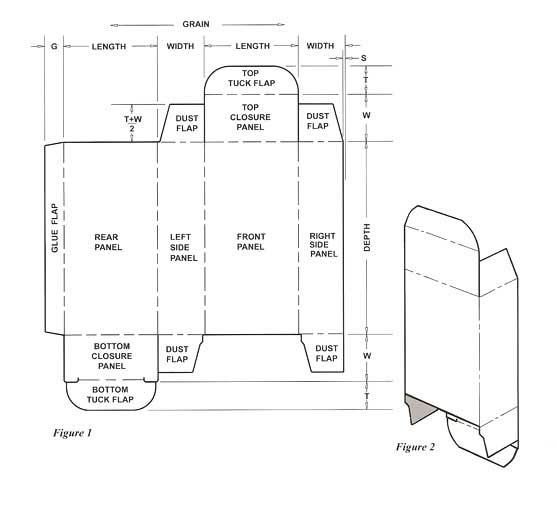

The folding carton can be divided into tubes and tray carton packaging. Tube carton box itself was a vertical-shaped, suitable for vertical bottle of wine, cosmetics, medicines and other packaging. Tray carton packaging is the most widely used in supermarkets, from food and textiles and then to the grocery goods. The folding carton is generally no adhesive, tied to each other then locking cardboard for carton forming and sealing.

Glued carton, also known as hard paper case, it has better strength and beautiful appearance than the average folding boxes, giving a valuable sense, is commonly used in high-end merchandise and gift packaging. There are many types of glued cartons, can be summarized as roll cover carton, window style carton, displays carton, portable carton, closed carton, slide carton and set-up carton.

Roll cover carton means this structure is to cover the body and the box combined with the cover side of the body fixed on the other side to open the folding carton. Because of the structure is simple, and more convenient to open and close, this kind of structure has been quite commonly used in carton box structural packaging design.

The window style carton exhibited surface on the box to make it transparent, so that consumers can see partly or full of the contents. The window size or position mainly based on the product features and graphic design for scientific, rational, beautiful purpose.

Displays carton, also known as "POP" box available for advertising and display, and can fully show the shape of the packaging. Displays packaging can be divided into two categories: one is without lid; another is with a lid, the lid can be opened for exhibition, closed for transportation.

the box biggest feature of portable packaging is easy to carry, it can be portable carton box. This modeling structure equipped with a handle on the box body. the handle part can be attached or made by the cover and side face extension mutual lock

The characteristics of closed packaging is fully enclosed with good security, ease of use. Closed cartons inserted holes along the open line tearing open the form mainly used for beverages and other disposable packaging.

Slide packaging also known as pull-out. The form of a double structure of another part of the pull in the form, and thus has a solid, thick, easy to use features. Set-up packaging refers to the related products together with ancillary packaging, or packaging of a number of the same product with more than combinations of packaging.

Thursday, February 23, 2012

Keyboard packaging design

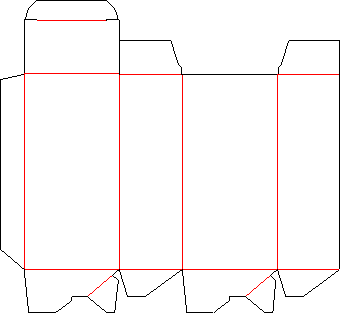

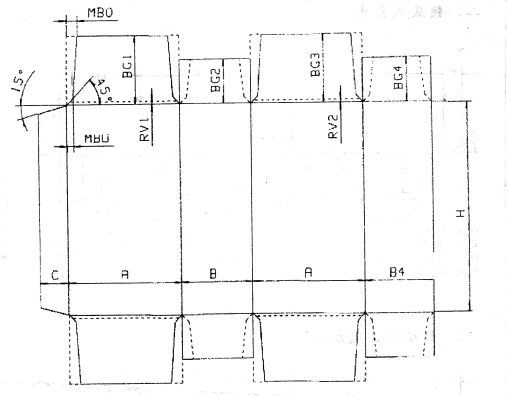

For keyboard box structural design, I mainly used Packmage CAD software, firstly I need to pick up the keyboard box template from its library.

Input the length, width, depth, caliper value etc. according to requirements. For example, L=400mm, W=145mm, D= 35mm, Cal=1mm, then we can save the settings with DXF format to generate the keyboard die cut template to facilitate the printing.

The second step is graphic design, we can use AI or Photoshop software for keyboard packaging graphic design, the keyboard box structural design also can be saved as PDF format, once we start graphic design, we can import the PDF format into Photoshop directly.

Once the graphic design finished, we can import the graphic design into Packmage CAD software to texture with the keyboard structural design, the we can check the 3D box modeling via 3D module.

See, the whole keyboard packaging design process is easy, try it yourself now.

Wednesday, February 22, 2012

How to check the carton box structure with 3D module

For box structural designers, when design a carton box template for clients it is very hard to check whether the box structural design is reasonable or not without physical reference. In this article we will discuss how to use Packmage CAD software 3D lines mode to check the rationality of the carton box.

At first, we need to find out a die line template in Packmage CAD box template library, for example, a shoe box template.

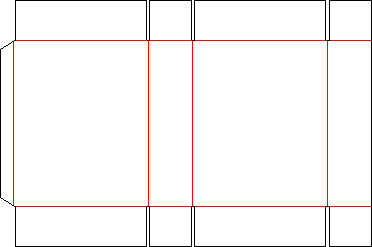

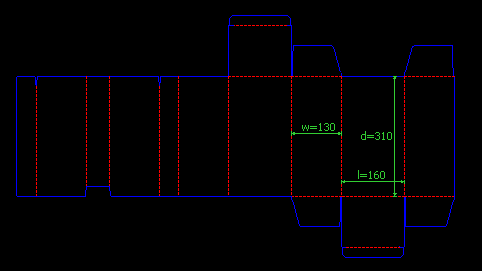

The photo above is the die line of a shoe box template, there has a interior lock structure on the lid of the shoe box. Once we finished the structural design of the shoe box according to the required size, we will go to the 3D mode check the structural design.

Look at the photo above, we are still not clear for certain size details via this 3D box modeling picture, or doubt the whether the sizes of shoe box are reasonable or not. For example, the lid structure of the shoe box can not be seen completely.

In Packmage CAD software, we can switch to lines mode by press short cut key L in the 3D interface.

During this mode, we can check the whole structure of the shoe box clearly, and the whole process is easy enough. However, one thing we need to pay attention, because the 3D module displays the material of the shoe box, which means it will display the caliper of the paper, so before we use line mode to check the box structure in 3D module, we have to change the caliper value into 0 in Parametric design interface.

Monday, February 20, 2012

Fast food packaging design

Good fast food packaging design should protect food quality as well as enhances customer satisfaction by making it easier and neater to eat large, messy sandwiches. Furthermore, the design should be:

· Enhanced product quality and integrity

· Superior heat retention and moisture absorbency/loss ratio

· Sales building tool for drive-thru

· First in source reduction, environmentally responsible

· Unique and fun for consumers

· Cost-effective

Here we mainly introduce a fast food packaging design, pizza box packaging. Firstly we can search pizza box templates on Packmage CAD website, it classified the box templates according to their usages.

Look at the pizza box templates above, the structure is very simple and intuitive, but it considered the factors listed as follow:

1> Self-locking structure, this kind of box template structure can be transported unfolded to save cost and facilitate users use them at any time. Furthermore, those box templates is healthier to load fast food because it do not have to be glued.

2> The pizza box template has holes for ventilation to keep food fresh and it can be heated with micro-wave.

Once the pizza box template parameters has been modified according to requirements, we can check the blank sample in Packmage CAD 3D module.

The next step is the graphic design of the pizza box template, it requires a combination of skills. On one hand, professional designers need to know how to create designs that coordinate with the client's branding strategy. On the other hand, food package design must contain important information about the food's ingredients and nutrition.

Carton box structural design FAQ

The carton box packaging especially the corner of the box can be easily crushed, deformed, broken during transportation if the box size is too large. If the box is just fit for the product, the pressure will be on the product, normally the product can afford more pressure than the box. You just need to find the highest point of the product or the most prominent position to get the length, width and depth of the product. The following are few FAQ in carton box structural design.

Q1: There's a carton box, the size of the product inside is 20cm*20cm*25cm. What's the size of the carton box which could save paper the most? Why? Caliper 1mm.

Answer: 20.1*20.1*25.2, because there're two flaps on the top and bottom of the carton box, so the caliper doubled add to the depth of the box. The box especially the corner of the box can be easily crushed, deformed, broken during transportation if the box size is too large. If the carton box is just fit for the product, the pressure will be on the product, normally the product can afford more pressure than the box. You just need to find the highest point of the product or the most prominent position to get the length, width and depth of the product.

Q2: 1、Which box structure design is more reasonable between the following two boxes? Why?

Answer: the box on the left side has more reasonable structure, the tuck style is more convenient.

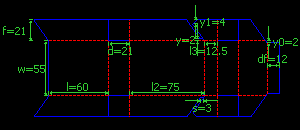

Q3: Check the following photo, see if the value of the e and s2 are reasonable, if not, how to correct them?

Answer: the value of these two parameters are not reasonable. The correct value should be e=s2+2, when the tuck inserted into the box, they matched properly.

Q4: check the photo in Q3, how to set the offset? Why?

Answer: usually the offset of cardboard can be 0.5mm, mostly 1mm, the offset of corrugated cardboard should related to the caliper, usually it is half of the caliper.

Q5: Find out the error of the parameters in the following photo and correct them, unit mm caliper 1.5mm

Answer: D2=79

X3=4.5 there will be 3 times caplier after folding

F5=79

D3=78.5

Mostly of them neglected the offset, the value isn't absolutely right, but the offset should be considered.

Q6: The print factory use certain paperboard for the following carton box structural design, the dust flap area has been crushed times, how to deal with this situation while keep the same paperboard?

Answer: Here we can use double folding line or fold on both the front and back side.

Thursday, February 16, 2012

Wednesday, February 15, 2012

Carton box packaging structural design

1> Overview

Judging from the literal meaning of packaging, we know packaging mainly include two meanings: packaging structural design and packaging graphic design. Packaging structural design through improve or re-design the structure of the packaging which not only facilitate the protection, transportation and storage of the products, but also help to boost the sales. Packaging graphic design mainly focus on series packaging graphic design related to company image advertising, description and sales of the products etc.. So packaging design mainly include structural design and graphic design, however, mostly packaging design focus on the graphic design, the structural design of the packaging has been ignored.

2>The importance of packaging structural design

People usually split the wrap and design process of packaging, it has been quite commonly phenomenon that mostly packaging paid great attention on the graphic design and ignored its structural design in the commodity competition. The packaging has been updated and replaced continually in order to suit for the intense competition. Although it can boost sales through this kind of strategy, it also bring negative impact on the company. On the other hand, packaging structural design could also make a pivotal role on the product sales because an excellent packaging structural design could not only display the product better, but also ease of use for customers. So we need to get together the wrap and design process which means the importance of packaging structural design can not be ignored.

3>Changes in the structure of carton packaging

Mostly carton box packagings keep the Stereotyped structure in our daily life. As we said before we should connect the packaging structural design together with graphic design. Here we mainly introduce the carton box structural design. The form of carton packaging can be summarized as some basic forms then improve and change their basic structures.

①Changes of form

The changes of form means cut and combinate the original form on the basis of geometry to generate new structures of forms. It mainly include the increase, decrease, combination concave and convex of geometric surface. The diversity and richness of carton packaging structure can be realized through those changes of form.

②Changes of surface

The changes of surface is mainly through the adjustment of the structure lines and changes on the form of the surface. The adjustment of structure lines means adjust the structure lines of carton packaging surface while keeps the basic structure the same. For example, Window style carton packaging could display the product intuitively which could boost the sales indirectly.

③Changes of lines

The Lines in packaging structural design means the contour lines of carton box and the intersecting lines between its surfaces. So the changes of lines basically kept the original structure, it mainly through the adjustment of the carton box contour lines, such as change the straight line into curve or broken line etc. Different line has different presentation character, thus the carton box packaging style becomes rich and versatile.

④Special structure

We've mentioned above the packaging structure design mainly start from the geometry, which means connect the packaging structure together with the product form closely. Through the special structure of the carton packaging could not only display the product intuitively but also attract more customers. The special structure design could start from 3 aspects: commodity forms, usages, interesting.

4> The meaning of the carton packaging structural design

The carton box packaging structural design is very important in the intensive competition. At first, it is not only facilitate the usage by customers, but also facilitate the manufacturer and sellers. Secondly, packaging structural design in favor of product protection, transportation and storage. Thirdly, packaging structural design display the product better which could potentially promote the sales.

In all, we know packaging design include structural design and graphic design, we can not split these two works, they should be complementary exist, excellent structural design provides rich changes of the structure, which increased the expression of the packaging graphic design and then promote the product sales. So we should connect both structural design and graphic design, pay attention to packaging structural design.

Tuesday, February 14, 2012

Packaging functions

1> Protective function

The product must be falling down, protected, and suffers vibration during transportation. Perishable food such as fruit must be of rigid packaging, such as laminated container are protected. In addition, the packaging must be capable of withstanding without a variety of static and dynamic loads to which it is subjected to during transportation, handling and storage. The assets are common, the protection from climatic conditions such as temperature, radiation, humidity, rain and sun, which may require different packaging measures.

2> Loading and Transport function

Easy management of activity is the development of transport packaging so it will be carried out, lifted, moved, are defined and fixed easily, efficiently and safely. The packaging is a crucial factor on the efficiency of the transportation, processing and storage of goods. Loading and transport function makes demands on the outer packaging by weight of the goods are placed inside and convenience packaging. The package of power is necessary for the installation of the goods on the other hand, the close relationship between the load and the transport-function displays, and protective.

3> Sales and Marketing

The purpose of this function make the sales process easier and more effective. The promotional material on the packaging is designed to attract the attention of potential buyers and have a positive influence on purchasing decisions. Promotional materials for the packaging plays an important role in the sales package, because it speaks directly to the consumer. This is only a minor role in the original packaging.

4> Storage function

Packaging materials and containers are required for packaging of goods must be stored in different places and for the packaging and all contents of the package were used. The packaging should also be the repository.

In addition, the package also warranty and service function, package, and the basis for brand products, consumer protection and product liability. There are legal requirements that the goods are clearly marked, indicating their nature, date of composition, weight, number and expiration date, etc. Packaging plays many functional roles for content protection, but perhaps the most important work is still regarded as to help sell the product at the point of purchase.

Monday, February 13, 2012

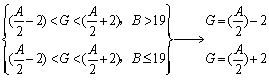

Tubular box structural design

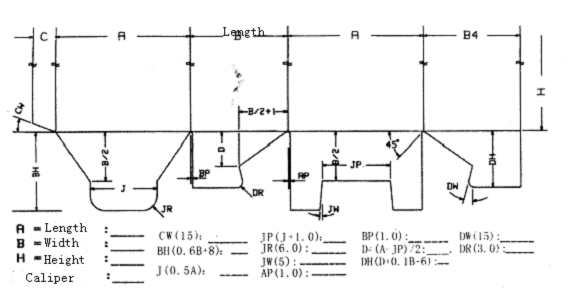

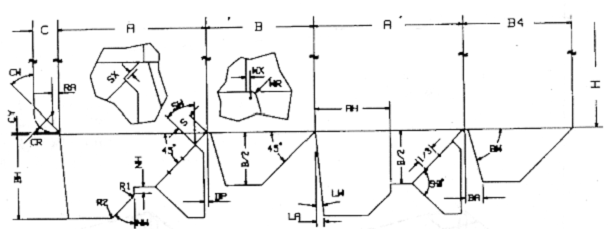

The theory of carton box design is a little complicated, In this article we will talk about the structural design formula and some commonly tubular box structure.

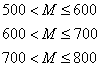

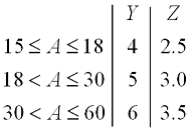

| Size | E | EX | B4 | V | FX |

|

| D=Caliper | ||||||

| <0.45mm | B-D | D | B-D | D | D |

|

| 046-0.65mm | B-D | D | B-D | D | D |

|

| 0.66-0.99mm | B-D | D | B-D | D | D |

|

| 1.00-1.80 | B-D | D | B-D | D | D |

|

| Size | ZX | Z4 | YH | S | N | FS |

| D=Caliper | ||||||

| <0.45mm | 3 | 3 | D+0.5 | D | F/4 mm | D |

| 046-0.65mm | 3 | 3 | D+0.5 | D | ||

| 0.66-0.99mm | 3 | 3 | D+0.5 | D | ||

| 1.00-1.80 | 3 | 3 | D+0.5 | D |

Note: When FX and Y equal 0, E=B

|

| 17mm<=A<=30mm | 30mm | 100mm | A>150mm |

|

| F=10mm | F=13mm | F=15mm | F=18mm |

| -----C----- | ----YZ------ | -----G----- |

| Glued Piece

| Rule

A>60 Y=7.5,Z=5.0

| Dust Flap

Formula1

Formula 2

The following can be ignored ------------------------------ Note:The following parameters can be changed according to requirements G=1/2 or G=B4

Formula 3

|

Structure of the end of the tubular folding carton box

1、Tuck end

2、Lock-End

3、Self Lock End

4、Glue End

Sunday, February 12, 2012

Cardboard packaging boxes design and production

There're lots of complicated steps before a cardboard packaging boxes produced in the factory, each step can not be wrong. The main production process of the packaging box can be divided into: Design-> Design Draft->Final Design->Film ->Printing template->Packing.

For packaging designer, the work mainly include draft design and some prepress works:

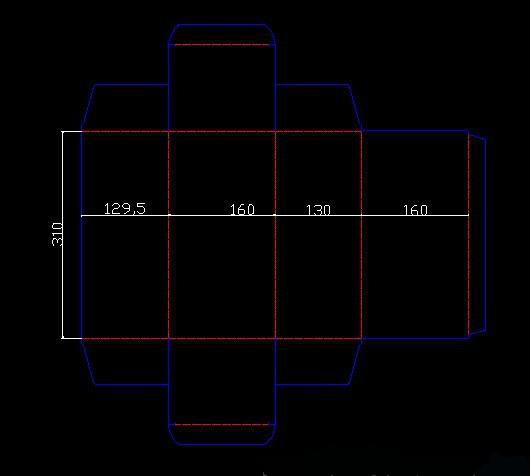

1> Confirm the cardboard type and the size of the packaging box, for example, if the product size is 150*120*300, the designer should bear in mind the virtue spaces to input and out the product. The preliminary width of the flat pattern would be: 160+130+160+130, here we do not consider seal width and offset. The hight of the packaging box can be 310 according to the same reason, then the length, width and hight of the packaging box would be 160*130*310. According to the weight of the product the designer can choose related cardboard type because the cost must be take into consideration here. For example if we choose 350g ivory board here, caliper 0.5mm.

2>Drawing the die line according to requirements with CAD software. Offset shouldn't be ignored during this process.

.

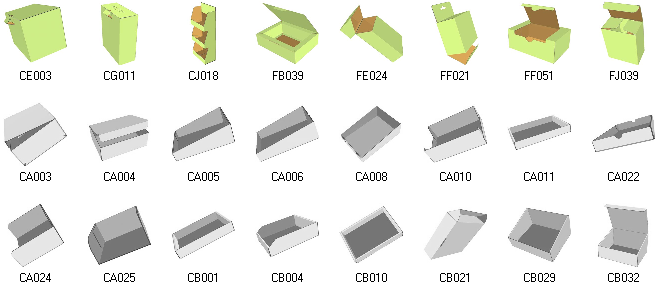

.

Lots of people in packaging industry might not know much about the packaging box structure, or haven't spent too much time drawing the box structure on the computer, here we can use Packmage CAD software, first user need to download and install it. Then we can login the software choose box template from the library.

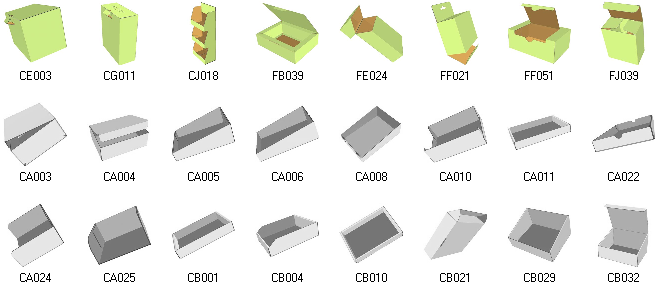

In Packmage CAD software library, all the box templates are listed as folding, unfolding and half-folding status, the colored boxes have been activated, the gray boxes need to be activated, and the box templates are classified as material, structural and usages, which is more intuitive and easy for user to select the right box template. If we chose FJ039 for example.

Modify the length, width and depth with 160,130 and 310. caliper 0.5. Once the box structure confirmed, it can be exported as DXF format directly from packmage CAD software, ordinary laser die-cutter has CAD plug in for bridges and calculate the total length of die-line and folding line.

The next step is to design draft. Designer can import the structural design into photoshop for graphic design. Then import the graphic design into Packmage CAD software to match with the structural design to check the 3D color sample. When the final design confirmed, if the quantities of the boxes are huge, it should proofing first, there should have prototype machine, also called box cutting machine.

There are two more processes called Film and Print plate need to be done before producing the box. There're 3 ways to check the final effect before printing:

1> Get the high definition draft before film(It's cheap but not so accurate);

2>Get few digital print samples, after confirmed then start film and printing if the quantities are huge, else digital print directly.

3>Ask the film company print few samples when making film, that's the most traditional way, the cost is a little expensive and time consuming.

Software might be used: Photoshop and AI for graphic design, Step and repeat(CDR, In design, Quarkxpress etc.)

After this step, we will need to make printing template and send to printing factory for massive production. The last step is Packing, all the cardboard boxes are flattened and packaged into the boxes to falicitate transportation.

During these steps, the hardware machine need to be used include: Computer, printing-down machine, print machine, prototype machine, laser die-cutter, Zapi machine and glued machine.

Software: AI,PS, CDR and Packmage CAD software work together to save time.

Wednesday, February 8, 2012

Cigarette case design

Packmage CAD software is a free packaging design software for corrugated cardboard and folding carton box design. It has a rich box templates library classified as the box material, structure and usages. The first step is to find out the cigarette box template in the library.

From: http://ping.fm/swfMC

Cigarette case design

To start the cigarette case design work, usually we need to draw the die line on CAD software and doing graphic design work on photoshop software. For skilled packaging designer it is easy, those work can be done in hours. In this article I'd like to suggest another way for cigarette case design.

Packmage CAD software is a free packaging design software for corrugated cardboard and folding carton box design. It has a rich box templates library classified as the box material, structure and usages. The first step is to find out the cigarette box template in the library.

In Packmage CAD box templates library, all the box templates are listed as 3D folding photo which is much more intuitive for user to find out the box. It will show the die line draft together with half-folding and unfolding photo once user selected one box template. Here we can find out the cigarette box template ID is FE024, then we can click to check the details and open it to modify the parameters such as length, width, depth, caliper etc. Because there's certain standard of the cigarette case, after the box templates opened you can adjust the size according to your need, here we choose the default value as the standard size, then you can export the file of the structural design.

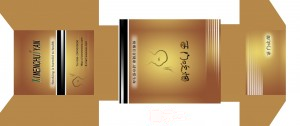

The second step is to use photoshop software for graphic design according to the size of the cigarette case.

Save the graphic design with in two JPG format files. Attention: the size of the cigarette case in graphic design should be the same with the one in structural design, when start the texture process in Packmage CAD software, the two files could be matched automatically, you do not have to adjust the size and position. You can take the size in the structural design interface as a reference when starting graphic design.

After texture the graphic design together with the structural design, user can check the color sample of the cigarette case in 3D module. Then modify and confirm the graphic design in photoshop software according to the 3D display of the cigarette case.

After checked the 3D folding again, the cigarette case design finished, the final design could be the effect list in the following photo.

With Packmage CAD software, the designer do not have to be highly skilled, the whole packaging design process is easy and fast. What are you waiting for? Download Packmage CAD software and start your packaging design now.

Monday, February 6, 2012

What's packaging design for?

From: http://ping.fm/0Syys

Sunday, February 5, 2012

What's packaging design for?

From: http://ping.fm/ICvCx

Wednesday, February 1, 2012

Free carton box packaging design software

Packmage CAD offers a rich box t

From: http://ping.fm/p2u1u