In the carton box production process, the creasing part is very important, it is not only affect the carton box quality also affect the carton box production cost. There are 3 commonly creasing issues listed below:

1. Irregular creasing line

The creasing line with the ridge began the process after the fingerprint folding substrates favorable pressure. The main reason that causes the irregular line card slots folding creases are too large, if the thickness of the panel began with the grooves of the paper, and custom rounded a corner .. Knife consecutive solid insufficient sealing knife, steel pipe is very narrow, and so Irregular folding carton approach exception to replace steel wire line buffer paper slit width settings as appropriate, increased thickness of the steel wire cutting Paper buffer opening angle model in the form as a strong set of hand knives feel appropriate to apply the knife seal.

2. Uneven pressure

We know that the creasing line is caused by the window wrinkles, creases or folds extrusion. In the production of the carton box, at the end of the line is under the control strain. The

principle of cardboard into the two slots solid surface (male and

female) for the printing cylinder is damaged, the internal structure of

paper fibers, thereby forming a sheet of paper in the hierarchy of

concave and convex lines of external links. Split the packet add lines 90 or 180 degrees is connected, a layer of paper sizing internal folding (grip) completely.

There

are two cases, causing uneven pressure on the box folding process: the

pressure a little bit irregular uneven.If can knife, irregular lines,

this time to set a balanced array so that the platform also powers

uniform.It attack fiber paper, the paper is the theme cut line vertical and horizontal better effect. Another

serious unevenness.If back and forth to the four corners of the

platform phenomenon heavy irregular pressure should be monitored when

they wear like a pendulum must be strong, to replace worn-out, otherwise

you have to adjust the pressure of the four thickness of constant

pressure.

3. Burst

Breakage

refers to the longitudinal cutting cardboard, folding, bending occurs

in the first and often, especially in dry weather. Wrinkles form when (stamp) is inserted into the slot, there are three forces. The

pressure on the surface tension of the cardboard train and the three

forces in addition to the permanent deformation Council also reduce the

adhesion between the layers of fiber. Break

during the folding of the paper surface, said inner layer of stress is

responsible subjected to pressure, when the pressure exceeds the

adhesion between the fibers of the paper, cardboard, paper fiber becomes

internal bend.The It is soft and gentle pressure can be too, if more

power than cardboard box is divided into lines. This occurs in many situations, such as clarification of paper, card holder, excessive shock pressure, etc.

In

general, the quality of the carton box template requires not only the field of technical

issues, such as pressure, strength and level of aesthetically beautiful

vision constantly exceed qualified, technique requires more points with

products of high quality proposals.

Simplify the carton box packaging design

Showing posts with label carton box. Show all posts

Showing posts with label carton box. Show all posts

Monday, December 10, 2012

Monday, September 17, 2012

4 processes of the carton box production

1. Carton box design

There is a great influence on the carton box structure design, which can be achieved with an automatic packaging machine. In many cases this is due to the size of some parts of the result in undue boxed product can not be implemented in automatic packaging machines, or the rate of loss would be huge. Well, there are a lot of software for the design of cardboard packaging to develop a structural model, for example, Packmage CAD software that takes full account of cardboard and locked in carton box structure design could help to improve the design work.

2. Carton box step and repeat

With respect to the orientation of the fibers in the paper, you can see the difference in normal conditions. During the printing process, the external force causes the paper warp, the cancellation of the external forces, the paper in its original state can be called tensile strength, related to the provision of paper fiber. Thus, during the test phase and under the authority of the box again, if possible, to maintain the parallel opening of cardboard fiber orientation in the direction of cardboard to ensure the opening of the window is not too large, and, by the tension of the paper fibers so that the shell after the formation of irregular irregularly during the molding process, so that packaging machine just a window to open the smooth production.

3. Carton box cutting and creasing

In the process of cutting a scoring matrix attachment quality knife key to quality of care is guaranteed, but also the condition that the arm. Direction of the line of folding carton has a certain influence on the width of the fold to have a width of fold line optimal, may be the direction of the bend lines on the printing surface is ignored.

The cardboard box can be deformed to the process of the packing line, the production seems smooth cardboard protection is very important. Habit was with boxes stacked to save the box. In general, try not to block the box at the bottom, which could break box folding.

4. Temperature and humidity affects on carton box

Varying conditions of temperature and humidity, window shapes change. New Product paper in a short time, the water content is too high, it is easy to bend and deform. Thus, the new document within a month or more to be saved, so that the moisture content of the paper can be accepted humidity.

There is a great influence on the carton box structure design, which can be achieved with an automatic packaging machine. In many cases this is due to the size of some parts of the result in undue boxed product can not be implemented in automatic packaging machines, or the rate of loss would be huge. Well, there are a lot of software for the design of cardboard packaging to develop a structural model, for example, Packmage CAD software that takes full account of cardboard and locked in carton box structure design could help to improve the design work.

2. Carton box step and repeat

With respect to the orientation of the fibers in the paper, you can see the difference in normal conditions. During the printing process, the external force causes the paper warp, the cancellation of the external forces, the paper in its original state can be called tensile strength, related to the provision of paper fiber. Thus, during the test phase and under the authority of the box again, if possible, to maintain the parallel opening of cardboard fiber orientation in the direction of cardboard to ensure the opening of the window is not too large, and, by the tension of the paper fibers so that the shell after the formation of irregular irregularly during the molding process, so that packaging machine just a window to open the smooth production.

3. Carton box cutting and creasing

In the process of cutting a scoring matrix attachment quality knife key to quality of care is guaranteed, but also the condition that the arm. Direction of the line of folding carton has a certain influence on the width of the fold to have a width of fold line optimal, may be the direction of the bend lines on the printing surface is ignored.

The cardboard box can be deformed to the process of the packing line, the production seems smooth cardboard protection is very important. Habit was with boxes stacked to save the box. In general, try not to block the box at the bottom, which could break box folding.

4. Temperature and humidity affects on carton box

Varying conditions of temperature and humidity, window shapes change. New Product paper in a short time, the water content is too high, it is easy to bend and deform. Thus, the new document within a month or more to be saved, so that the moisture content of the paper can be accepted humidity.

Friday, June 1, 2012

Carton box step and repeat with Packmage CAD software

Carton box step and repeat process is the basic process for carton packaging manufacturing, it related to the profits rate of the printing factory, so how to save cost in this process is the most concerned topic in the printing industry. Packmage CAD step and repeat features could step and repeat single box template rapidly with optimized solution, if there are two or more carton box templates on one cardboard, it should step and repeat manually to get the best step and repeat solution to save paper.

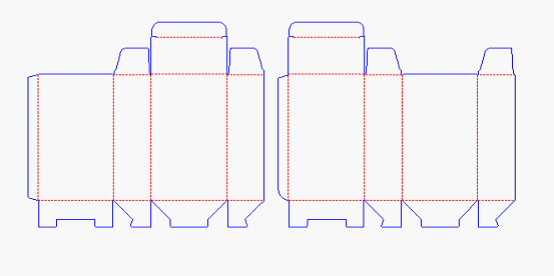

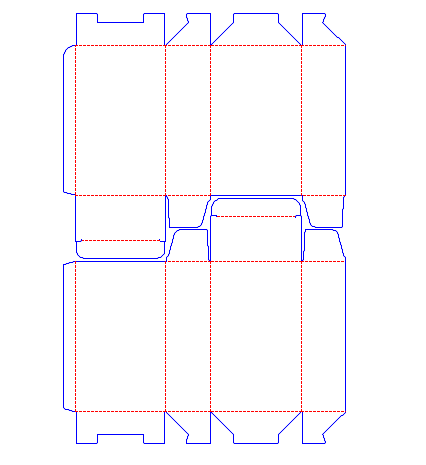

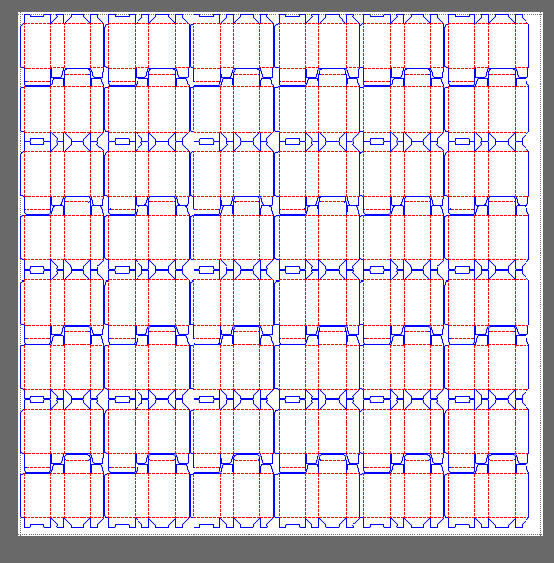

Please check the carton box templates above, they are from the same client and the quantities is huge, if we only select one box template to step and repeat,

there will be lots of waste during printing, the paper utilization is

much more lower than step and repeat them together. There's small

skills we could step and repeat them manually.

Firstly we could use the tools in the tools bar to adjust the position of the two box templates on the cardboard. Here we only need to Y flip the right box template, then move them together.

Secondly, Click Array button on the tools bar and input the quantities of the line and row and confirm.

In the cardboard, we can step and repeat 48 box templates, if we step

and repeat single box template on the same cardboard, no matter which

box template we choose, we could only step and repeat 42 of them.Apparently, we step and repeat them together could improve the paper

utilization to help the printing company save cost. For further

information about step and repeat, please check the Help documents on

Packmage CAD website.

| |||||

| Carton box templates |

Firstly we could use the tools in the tools bar to adjust the position of the two box templates on the cardboard. Here we only need to Y flip the right box template, then move them together.

| |

| carton box step and repeat |

| |

| carton box step and repeat |

Friday, September 23, 2011

Packmage carton box design software 3D Semi-auto lock carton box templates

|

| Semi-Auto Lock box templates FG001 |

|

| Semi-Auto Lock box templates FG031 |

|

Semi-Auto Lock box templates FG002  |

|

| Semi-Auto Lock box templates FG006a |

|

| Semi-Auto Lock box templates FG007 |

|

| Semi-Auto Lock box templates FG008a |

|

| Semi-Auto Lock box templates FG008b |

|

| Semi-Auto Lock box templates FG008c |

|

| Semi-Auto Lock box templates FG008d |

|

| Semi-Auto Lock box templates FG014 |

|

| Semi-Auto Lock box templates FG015 |

|

| Add caption |

|

| Semi-Auto Lock box templates FG022 |

|

| Semi-Auto Lock box templates FG027 |

|

| Semi-Auto Lock box templates FG030 |

Wednesday, September 14, 2011

carton box for packaging

Carton boxes are usually the most convenient way of packaging. Its organization and neatness are very convenient. They also assure protection and safety of the items being packed - particularly shipped or transported to another area or state, actually across countries. They are generally used for hard drive and moving.

When carton box used for packaging, choosing the right boxes for taking certain stuff is usually very important. Food packaging box with doughnuts, Chinese dimsums, and chicken wings are usually incredibly thin for easy disposal. Surely, you would n't want empty food packaging boxes around to keep or recycle. Electrical appliance ones tend to be larger and normally made of double-walled cartons. Corrugated carton box usually are what huge carton box are manufactured from. The more your flute, always better. They are the best choice for temporary storage area and transporting deliveries since the material is lighter. Fortunately they are environment friendly as most carton boxes these days are already created from carton coming out of recycled materials. Some of these are also manufactured from light woods. A example of these are your wine ones. Some are also made of styrofoams. These styro ones may be used for saving and transporting fresh fruits and vegetables from farms to food markets.

Now, assuming that you will possibly be needing boxes for packaging to move your home goods, it is always important to weigh and measure your items first before getting the right carton box for it. Packaging boxes are normally measured in three dimensions - depth, width, plus length.

Things which might be heavy and fragile need boxes which might be a lot a lot more thick and strong. If you are usually into a dried out good business, box printing is an excellent way of attracting prospects. The packaging box design can actually help promote your product. Things that are heavy and breakable need to have boxes that are a lot more thick plus sturdy. If you might be into a dried up good business, field printing is a good way of attracting prospects. The boxes intended for packaging design can actually help promote your products or services.

When carton box used for packaging, choosing the right boxes for taking certain stuff is usually very important. Food packaging box with doughnuts, Chinese dimsums, and chicken wings are usually incredibly thin for easy disposal. Surely, you would n't want empty food packaging boxes around to keep or recycle. Electrical appliance ones tend to be larger and normally made of double-walled cartons. Corrugated carton box usually are what huge carton box are manufactured from. The more your flute, always better. They are the best choice for temporary storage area and transporting deliveries since the material is lighter. Fortunately they are environment friendly as most carton boxes these days are already created from carton coming out of recycled materials. Some of these are also manufactured from light woods. A example of these are your wine ones. Some are also made of styrofoams. These styro ones may be used for saving and transporting fresh fruits and vegetables from farms to food markets.

Now, assuming that you will possibly be needing boxes for packaging to move your home goods, it is always important to weigh and measure your items first before getting the right carton box for it. Packaging boxes are normally measured in three dimensions - depth, width, plus length.

Things which might be heavy and fragile need boxes which might be a lot a lot more thick and strong. If you are usually into a dried out good business, box printing is an excellent way of attracting prospects. The packaging box design can actually help promote your product. Things that are heavy and breakable need to have boxes that are a lot more thick plus sturdy. If you might be into a dried up good business, field printing is a good way of attracting prospects. The boxes intended for packaging design can actually help promote your products or services.

Friday, September 9, 2011

carton box templates- self-locking trays

|

| Packmage self-locki |

|

Packmage self-locki |

|

| Packmage self-locki |

|

Packmage self-locki |

|

Packmage self-locki |

|

Packmage self-locki |

|

Packmage self-locki |

|

| Packmage self-locki |

|

| Packmage self-locki |

|

Packmage self-locki |

|

| Packmage self-locki |

|

| Packmage self-locki |

|

| Packmage self-locki |

|

| Packmage self-locki |

|

| Packmage self-locki |

|

| Packmage self-locki |

|

| Packmage self-locki |

|

| Packmage self-locki |

|

| Packmage self-locki |

Thursday, September 8, 2011

Boxes classification in packaging design industry

Boxes are one of the most useful items for packaging design. They usually are widely used for the large number of purposes,in the packaging industry packaging includes a massive range of merchandise including bottles, pieces of furniture, electronics and physical equipment, sports equipment and even art works, etc. There are different kinds associated with boxes for different kinds of packaging design. The designs, sizes and the type of material of the packaging boxes depend on what they have to contain, There're many classifications such as corrugated box, carton box, wood box, bulk box etc. They can also be classified according to the form of purpose they will serve, for example boxes for containers, postal, mugs, picture frames, stationery and so on.

Cardboard box is incredibly common for presentation purposes. There may be four different varieties of cardboard boxes regular, heavy duty, white and triple wall. The first kind is for single wall usage and is made of corrugated kraft layer. The inner aspect is recycled transverse flute. They are often packed flat as well as the flaps need to get taped often. The heavy duty pressboard box is designed to reduce the entire requirement for product packaging design, thanks to its large space, increased strength due for you to double layered surfaces and 7% lighter in weight materials.

White cardboard boxes can be of standard, postal, cake, solid board in addition to recycle bin types. The triple wall membrane cardboard box incorporates a layer of kraft on the exterior and has remade flute. They have corrugated layers. Corrugated boxes are very useful seeing that shipping containers. Sometimes they have inner components like blocking, shock absorption and bracing pertaining to fragile contents. This type of box may typically contain labels, bar codes printed on that and graphical designs. Stacking strength is an extremely important parameter for cardboard boxes. This implies the resistance in order to crushing.

There is another kind of box that is termed the bulk box. They are constructed of corrugated fiberboard, that is double or triple wall. In large industries, there might be boxes that are made of steel and metal to be able to withstand great forces, weights and influences. Different kinds involving standardizations are targeted to be satisfied like for wirebound shipping cardboard boxes, wood-cleated panel board ones and many others. The words carton box, made of poster board, and box, in many cases are interchangeable. Consumer packs are packed in cartons.

Some other varieties of boxes could be made mirror, dish packs, legal handbag, book, wardrobe as well as mattress boxes. Most of these boxes carry just what names imply especially, legal tote containers are meant to carry files and folders. Other boxes include things like those meant with regard to postal or posting purposes, mugs and packing electronic products, which are often fragile.

Cardboard box is incredibly common for presentation purposes. There may be four different varieties of cardboard boxes regular, heavy duty, white and triple wall. The first kind is for single wall usage and is made of corrugated kraft layer. The inner aspect is recycled transverse flute. They are often packed flat as well as the flaps need to get taped often. The heavy duty pressboard box is designed to reduce the entire requirement for product packaging design, thanks to its large space, increased strength due for you to double layered surfaces and 7% lighter in weight materials.

White cardboard boxes can be of standard, postal, cake, solid board in addition to recycle bin types. The triple wall membrane cardboard box incorporates a layer of kraft on the exterior and has remade flute. They have corrugated layers. Corrugated boxes are very useful seeing that shipping containers. Sometimes they have inner components like blocking, shock absorption and bracing pertaining to fragile contents. This type of box may typically contain labels, bar codes printed on that and graphical designs. Stacking strength is an extremely important parameter for cardboard boxes. This implies the resistance in order to crushing.

There is another kind of box that is termed the bulk box. They are constructed of corrugated fiberboard, that is double or triple wall. In large industries, there might be boxes that are made of steel and metal to be able to withstand great forces, weights and influences. Different kinds involving standardizations are targeted to be satisfied like for wirebound shipping cardboard boxes, wood-cleated panel board ones and many others. The words carton box, made of poster board, and box, in many cases are interchangeable. Consumer packs are packed in cartons.

Some other varieties of boxes could be made mirror, dish packs, legal handbag, book, wardrobe as well as mattress boxes. Most of these boxes carry just what names imply especially, legal tote containers are meant to carry files and folders. Other boxes include things like those meant with regard to postal or posting purposes, mugs and packing electronic products, which are often fragile.

Tuesday, September 6, 2011

Packmage 3D carton box templates-glued trays

|

| Packmage folding carton box templates- |

|

| Packmage folding carton box templates- |

|

| Packmage folding carton box templates- |

|

| Packmage folding carton box templates- |

|

Packmage folding carton box templates- |

|

| Packmage folding carton box templates- |

|

| Packmage folding carton box templates- |

|

Packmage folding carton box templates- |

|

Packmage folding carton box templates- |

Subscribe to:

Comments (Atom)