If you're thinking of avail cardboard boxes on yourarduous packaging stuffs, Corrugated cardboard is the best option available. In case you are now thinking that what this corrugated cardboard is focused, the truth is, it is nothing distinct from a cardboard, moreover it is easily obtainable in single, double and triple walls. So now you don't need to concern yourself with the damaging in the precious stuffs when you are heading towards long journey because corrugated cardboard boxes make sure you about their safety. A number of its benefits are listed below:

Cost-efficient- Given that the corrugated cardboard is renewable in the wild, it is usually provided at minimal cost.

Safety-As there aren't any sharp edges or secedes, you can certainly carry and it is safe.

Environmental friendly- As the boxes are produced from recycled materials, they are renewable and therefore can be utilised continually.

Easy printing: The box lets you to mark your company names, logos etc easily, as other material hardly allow.

Completely durable: The boxes were created with material that includes along lasting guarantee.

The Corrugated cardboard also referred as brown boxes, it is not made with any ordinary cardboard; rather it holds three complex layers of cardboard that are called outer liner, which is the exterior of the box, inner liner which is a hardcore and prevents the box from heavy damage. Then final layer is the Fluting medium that maintains the entire reliability of the box, it can retain extreme heat and pressure. You ought to be thinking which material is utilized for producing these boxes, well staple material for constructing these boxes is pine tress, and the companies manufacturing these boxes probably have their very own land in which these trees are grown. Moreover there are chemicals involved in the procedure for their manufacturing, a fibrous pulp is made, and this pulp is employed for manufacturing large rolls of Kraft papers through a process. However corrugated boxes are manufacturedby the entire recycling, which involves breaking of the box and technique is same as making corrugated box from scratch.

Packmage, a brand name that offers corrugated cardboard boxes design services worldwide. They shoot for an extensive improved packaging design that offers the customers best service, company expert team design every type of boxes that serve the client using a best possible way, you should have adetailed view of the services at www.packmage.com.

Simplify the carton box packaging design

Showing posts with label Packmage. Show all posts

Showing posts with label Packmage. Show all posts

Wednesday, July 27, 2011

Tuesday, July 19, 2011

5 steps to master carton box packaging design

In Packaging industry, Packaging design is always the hottest topic, no matter design studio, prototype factory, packaging manufacturer, even packaging machine factory considered about what they need to improve to help client benefiting the packaging design, there’re lots of excellent software for carton box packaging design, such as artioscad, cimpack, autocad etc. Today I would like to introduce a new carton box packaging design software Packmage to help users get their carton box designed in a few steps:

The first step, select box from the library, Packmage carton box packaging design software offers hundreds of boxes in the library and the quantities updated every week.

| ||

| Packmage box library |

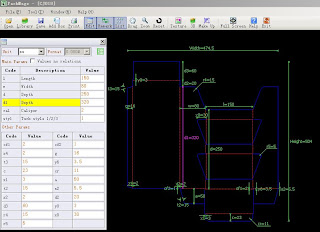

The second step is parametric design, modify the box size according to your requirements.

|

| carton box parametric design |

Here you can modify the parameters in the tablet of the left menu, the box will be adjusted automatically after the parameter value changed, also the user can check the information such as box size, the total length of die-line and folding-line, paper utilization etc.in the parametric design interface.

The Third step is texture, in the texture interface, user can import the graphic design of the box.

| |

| texture with graphic design |

Users can texture the whole box or each individual part of the box according to their requirement, the 4 direction keys can be used for matching the graphic design with the box structural design.

The fourth step is 3D box modeling, with this feature user can check if there’s any flaw with the box structure design during the modeling process.

| ||

| 3D box modeling |

The Packmage 3D interface is very friendly, user can move the mouse to the button to know the feature. With Packmage 3D users can get the 3D box effect with photo or video so that they can show to clients immediately without proofing.

The fifth step is step and repeat, after the box structure design and graphic design finished, Packmage makeup module can offer the best sort solution for box step and repeat.

| ||

| Packmage box step and repeat |

With this module, user can step and repeat one or more boxes in one cardboard in order to save cost, also it offers information like paper utilization rate, the total length of die-line, folding line etc. The final file can be exported as DXF or PDF format.

Isn't it easy for carton box design? If you still confused about how to design a carton box you can check Packmage video introduction directly.

Monday, May 30, 2011

Dieline in Packmage carton box design

What is a Dieline?

The dieline is the template for a package. It’s a flattened outline of the cutlines and folds. You cannot create a product package design without one – so don’t even try.If you took apart a cereal box and flattened it out, you’d be looking at the dieline. The edges of the box are the cutlines and all the seams and creases are the folds and overlaps. It’s basically supermarket origami that must also be sturdy, functional and do a darn good job of attracting the consumer’s interest.

Your dieline must be perfect. You’ll be creating an extremely tight layout, a pixel perfect balancing act between competing design elements, so even loosing an eighth of an inch will often require a reworking of the entire package. This is why I never start a package design without a finalized dieline. Otherwise I’m just guessing and ultimately wasting my time and giving my client a false sense of accomplishment.

So How Do You Create a Dieline?

If you get a finalized dieline straight from the printer (the most likely scenario), it will have the bleed requirements and all the manufacturing notes already on it. This is ideal and if you have that you don’t need this tutorial.However, sometimes you’ll be working with a client in the early stages. Perhaps they’ll send you a box from another product and direct you to make one just like it. Maybe they’ll FedEx you a bottle or jar and ask you to make a label that maximizes the container’s real estate. Or maybe they’ll send you the product itself and ask you to design a box, clamshell or blister pack to hold it. If this is the case then this tutorial is for you.

Labels and other two dimensional package designs are easy and you can generate perfect dielines for these on your own. However, unless you are reproducing an existing box, working from an existing dieline, or you have extensive experience in CAD applications, you can’t realistically create a perfect three dimensional package dieline on your own. However, you can start the ball rolling and then turn over your dielines, notes, and a sample of the product to a printer or manufacturer and they can use it as the basis for creating a working dieline.

Dieline in Packmage

For begginers, packmage predefined dieline in the box struture, you can check the photoes as follow:http://packmage.blog.com/files/2011/05/ZW001-buttomlocktray.jpg

Since Packmage predefined dielines and box shapes, it’s much more convenient for new user.

Packmage 3D box modeling new improvements

Packmage 3D box modeling features new improvements will be released soon, there are the details:

1> Solved the 3D high definition compatibility with 64-bits OS systems;

2>3D lights intensity and angles can be adjusted with nice presentation;

3>3D cardboard inside background color has been modified;

4>paperboard of hollow out clipping in 3D presentation improved.

1> Solved the 3D high definition compatibility with 64-bits OS systems;

2>3D lights intensity and angles can be adjusted with nice presentation;

3>3D cardboard inside background color has been modified;

4>paperboard of hollow out clipping in 3D presentation improved.

Subscribe to:

Posts (Atom)