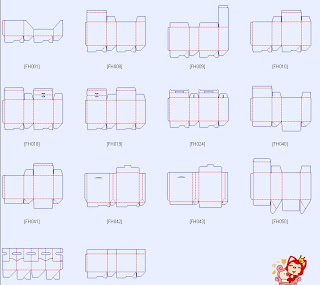

Boxes are used intended for any large number regarding purposes, but in the particular industries, they are mostly used regarding packaging. There are different kinds regarding boxes with respect to different kinds involving packaging. The shapes, sizes not to mention this materials belonging to the boxes depend on what they contain.

Boxes are some of this most useful items used for the purpose of packing. They are widely used in all the packaging industry with respect to packing a fabulous big range involving products including bottles, furniture, electronics in addition to mechanical equipment, sports gear and also even art works, among others. They have many classifications such as corrugated box, carton box, wooden box, bulk box etc. They can also be classified on the basis of one's kind associated with purpose they are going to serve e.g. boxes designed for bottles, postal, mugs, picture frames, stationery etc.

Cardboard box is without a doubt very common for the purpose of packaging purposes. There can be four different kinds from cardboard boxes: standard, heavy duty, white with triple wall. The first type might be pertaining to single wall usage not to mention can be made involved with corrugated craft layer. The inner part is recycled flute. They are often packed flat plus this flaps need to help you be taped often. The heavy duty cardboard package was made to reduce typically the overall requirement with regard to packaging, thanks to assist you to its large space, greater strength due that will double layered walls and even 7% lighter materials.

White cardboard boxes can be of standard, postal, cake, solid board in addition to recycle bin types. The triple wall cardboard pack has some sort of layer with craft on a outside and then has recycled flute. They also have corrugated layers. Corrugated boxes themselves are very useful as shipping containers. They often have inner components like blocking, cushioning and bracing regarding fragile contents. Such a new container may often contain labels, bar codes printed on the following not to mention graphical designs. Stacking strength is really a very important parameter meant for boxes. This signifies these resistance to crushing.

Some other classifications in boxes may be made mirror, dish packs, legal tote, book, wardrobe along with mattress boxes. These boxes carry exactly what a names imply not to mention in particular, legal tote boxes are meant with respect to carrying files not to mention folders. Other boxes include those meant for postal or mailing purposes, mugs and even packing electronic goods, which are often fragile.