Today, the growing demand of carton packaging led to the carton box design industry, it promotes differentiation and important products on the shelves. The materials used cardboard latter increasingly rare, special decorations and clever ways to check the box is, the boundaries between conventional products and high technology are increasingly blurred, more sales of products based on the design sheet.

Increasingly used carton packaging in cosmetics industry from the box to be included within the package. For

example, the material EPS impact protection alternating corrugated,

lightweight, inexpensive and easy to recycle, etc., in this view of the

card is the ideal material for eco-friendly packaging.

Cushion

wavy, not only has an excellent buffering capacity, and the ability to

meet the requirements of product positioning in the carton packaging, but also

the advantages of simple structure, efficient and easy to assemble. Now

many perfumes, cosmetics, and so the use of coating micro-corrugated to

improve the compressive strength of the paperboard in order to improve

the quality of the package. Corrugated thin and a variety of ways of saving high strength corrugated more environmentally friendly. Activity at a certain point, the products of the box are easy to recycle, reuse and is ideal for "green" packaging.

Among the four modern packaging materials - paper, plastic, glass, metal, paper and plastic packaging grows faster. Paper and plastic are the two most commonly used packaging materials which have played an increasingly important role in many fields, such as medicine, food and health, cosmetics and cleaning products. Based on the carton packaging has a larger space development, Model collapsible bag packaging machine and automatic high-speed lead meets the requirements for the packaging line and of printing and processing. Commonly followed by other multi-board applications, such as the quality of the performance requirements more stringent than users of paper products, which. To further increase the quantity of multilayer materials

Simplify the carton box packaging design

Showing posts with label carton box design. Show all posts

Showing posts with label carton box design. Show all posts

Tuesday, January 1, 2013

Monday, October 22, 2012

Carton box molding process

In

the design of the carton box, you must first meet the general requirements, open means that the main area of the board should satisfy

most consumers usual. Second,

we must consider the relationship between the carton box structure design and graphic design, it means that the structure of the design

according to the characteristics of the packed product, environmental

factors and the needs of users, it is reasonable is a design, infiltration, adhesive strips, dust flaps and other components. This is necessary for the general design principles meet and coordinate with the shape and design requirements. The shape and decoration must be an aesthetic point of view, focusing on the properties of a box. In

addition, the size and strength of the structure is also important in

the design of a box not only affects the appearance and quality of the

cardboard box, and the relative costs of production and circulation.

According to the method of forming a carton can be divided into a cardboard box and glued cardboard. Paperboard is generally made of cardboard (thickness of 0.3 ~ 1.1 mm) according to the cutting and creasing, folding, folding flat for transportation and storage of goods, to the load. The advantages of low cost of production and sale of carton, suitable for medium to high volume, flexible structural changes, but his strength is low. Carton with plywood, it can be folded into a flat plate, and are transported and stored in the solid body. With a good anti-Pearce and combat effectiveness, rigid box, in the general area, but the intensity of the work of production workers, are products, at low speed, and the cost is high and is suitable for jewelry.

In the carton box molding process the blank of cardboard and printing process primarily affects the quality of the carton. If the cut is bad, it will affect the flow in one carton, and also lead to lose if the print quality is bad, it will affect the beauty of a cardboard box and its function. Therefore, you should pay attention to the precision cutting and printing of a paper box. In the manufacture of laminated cardboard, gluing process affects the quality of the box itself, gluing and decorating the corners requires a sticky solid, and there are no bubbles, flat and smooth. Position of the logo and the model is not correct. Now, the bonding process can by gluing together many packages are made.

The carton box is not just a set of products has high artistic, so that the principles of the carton box design should be scientific, reliable, attractive, durable principles correspond. Designers should reflect the scientific development of the internal and external structure of a box, depending on the characteristics of the packaging industry, the environment and the needs of users and other factors, it is necessary to the, ease workload of security features to use and display a box, and the identity of the general effect, given the structural modeling and design.

According to the method of forming a carton can be divided into a cardboard box and glued cardboard. Paperboard is generally made of cardboard (thickness of 0.3 ~ 1.1 mm) according to the cutting and creasing, folding, folding flat for transportation and storage of goods, to the load. The advantages of low cost of production and sale of carton, suitable for medium to high volume, flexible structural changes, but his strength is low. Carton with plywood, it can be folded into a flat plate, and are transported and stored in the solid body. With a good anti-Pearce and combat effectiveness, rigid box, in the general area, but the intensity of the work of production workers, are products, at low speed, and the cost is high and is suitable for jewelry.

In the carton box molding process the blank of cardboard and printing process primarily affects the quality of the carton. If the cut is bad, it will affect the flow in one carton, and also lead to lose if the print quality is bad, it will affect the beauty of a cardboard box and its function. Therefore, you should pay attention to the precision cutting and printing of a paper box. In the manufacture of laminated cardboard, gluing process affects the quality of the box itself, gluing and decorating the corners requires a sticky solid, and there are no bubbles, flat and smooth. Position of the logo and the model is not correct. Now, the bonding process can by gluing together many packages are made.

The carton box is not just a set of products has high artistic, so that the principles of the carton box design should be scientific, reliable, attractive, durable principles correspond. Designers should reflect the scientific development of the internal and external structure of a box, depending on the characteristics of the packaging industry, the environment and the needs of users and other factors, it is necessary to the, ease workload of security features to use and display a box, and the identity of the general effect, given the structural modeling and design.

Thursday, September 15, 2011

Steps to design carton box manually

The first step for carton box design is to search or make a template. it can be almost all easily found from an existing box design such when retail packaging or perhaps shipping box. You could possibly even design the box your own. By ungluing your seams of an existing box you notice the box will probably unfold to a flat sheet of cardboard that is printed only on one side. It is fairly easy to modify a current box design or figure out a new design of your own.

The next step is graphic design of the box by graphic processing software just like PhotoShop. There are several ways to accomplish this. One way should be to take an picture using a digicam being careful to never distort the picture by taking this at an angle. Try to make image straight in. Another way to help transfer the put together is to start using a CAD program for you to recreate the outline together. In either circumstance you may need to store the primary outline in case you need remodifications.

Collect the photos that you are likely to use.They can be renderings of the merchandise or images utilized by a video camera. The images will likely also include your logo. It may be convenient at this time to finesse the pictures by using software to adjust color for example.

You may also want to crank out the text for the packaging. I find that it s better to use Word. Because word processing program will check grammar and spelling and it also relatively easy to paste into a graphics software.

After setting all the packaging features, you may need to expand the canvas size to possibly be larger than the box outline by perhaps an inch or maybe two. Make your canvas a widespread paper size so it can be published using easily available printers. If the package outline is usually small enough you could be able to make use of a typical color printer. Be sure to pick the printer papers that will provide you with the perfect results.

Obtain a well sized sheet of E or F fluted cardboard substance and glue printed out to the item. Do this simply by painting the surface of the cardboard lightly with a paper glue. But if your carton box packaging is reasonably large you may need to use wax papers to keep the actual surfaces apart until the print out will be properly positioned. At this stage, pull the become paper out becoming careful to maintain printout in position. Carefully smooth the finish to remove every ridges. This is going to take some care. Allow the glue cure in a single day.

After the glue has completely cured, using a pin number or needle hand techinque a hole in the registration points (a circles with X's or pluses in the mid). Make sure to be able to punch the holes straight up plus down for correct positioning. You will use the holes to position the folding traces which will end up being located on sleep issues, the inside unprinted side.

You'll need a tool for making the fold outlines. What I used was a real wood or metal panel tapered to your round point on one edge. The position is about 1/32 of an inch across. The panel is a number of inches wide leading to 1/8 heavy. It should possibly be longer than this longest fold line of the carton box packaging. That the tool is used is that the actual cardboard is put on a flat levels surface. The application is then aligned on the sign up mark holes, on the fold line, and struck with any hammer. The drive of the setback dimples the unlifelike along the collapse line and makes it much simpler to accurately retract. Repeat this for every single fold line.

The next step is to cut relieves in the print out. These relieves consists of slices along this fold lines on the printed side. To accomplish this line up the straight edge within the fold line subscription marks and meticulously cut a slit in the paper print only.

The final step is to cut the box outline, fold it along the fold lines as well as glue the tabs in place. When necessary use books, prevents of wood or maybe bricks to offer the box in appearance until the glue dries.

The whole process for carton box design manually is a little complicated, here I suggest you try packmage carton box packaging design software, which contains 400 box templates in its box library, all you need to do is to modify the box size to get the carton box design done, that's quite easy and can improve your work efficiency.

The next step is graphic design of the box by graphic processing software just like PhotoShop. There are several ways to accomplish this. One way should be to take an picture using a digicam being careful to never distort the picture by taking this at an angle. Try to make image straight in. Another way to help transfer the put together is to start using a CAD program for you to recreate the outline together. In either circumstance you may need to store the primary outline in case you need remodifications.

Collect the photos that you are likely to use.They can be renderings of the merchandise or images utilized by a video camera. The images will likely also include your logo. It may be convenient at this time to finesse the pictures by using software to adjust color for example.

You may also want to crank out the text for the packaging. I find that it s better to use Word. Because word processing program will check grammar and spelling and it also relatively easy to paste into a graphics software.

After setting all the packaging features, you may need to expand the canvas size to possibly be larger than the box outline by perhaps an inch or maybe two. Make your canvas a widespread paper size so it can be published using easily available printers. If the package outline is usually small enough you could be able to make use of a typical color printer. Be sure to pick the printer papers that will provide you with the perfect results.

Obtain a well sized sheet of E or F fluted cardboard substance and glue printed out to the item. Do this simply by painting the surface of the cardboard lightly with a paper glue. But if your carton box packaging is reasonably large you may need to use wax papers to keep the actual surfaces apart until the print out will be properly positioned. At this stage, pull the become paper out becoming careful to maintain printout in position. Carefully smooth the finish to remove every ridges. This is going to take some care. Allow the glue cure in a single day.

After the glue has completely cured, using a pin number or needle hand techinque a hole in the registration points (a circles with X's or pluses in the mid). Make sure to be able to punch the holes straight up plus down for correct positioning. You will use the holes to position the folding traces which will end up being located on sleep issues, the inside unprinted side.

You'll need a tool for making the fold outlines. What I used was a real wood or metal panel tapered to your round point on one edge. The position is about 1/32 of an inch across. The panel is a number of inches wide leading to 1/8 heavy. It should possibly be longer than this longest fold line of the carton box packaging. That the tool is used is that the actual cardboard is put on a flat levels surface. The application is then aligned on the sign up mark holes, on the fold line, and struck with any hammer. The drive of the setback dimples the unlifelike along the collapse line and makes it much simpler to accurately retract. Repeat this for every single fold line.

The next step is to cut relieves in the print out. These relieves consists of slices along this fold lines on the printed side. To accomplish this line up the straight edge within the fold line subscription marks and meticulously cut a slit in the paper print only.

The final step is to cut the box outline, fold it along the fold lines as well as glue the tabs in place. When necessary use books, prevents of wood or maybe bricks to offer the box in appearance until the glue dries.

The whole process for carton box design manually is a little complicated, here I suggest you try packmage carton box packaging design software, which contains 400 box templates in its box library, all you need to do is to modify the box size to get the carton box design done, that's quite easy and can improve your work efficiency.

Thursday, August 4, 2011

Carton box templates with 3D modeling effect-Glued Trays

These Glued Trays are all from Packmage packaging design software library, coming soon for more………………

Monday, August 1, 2011

cardboard box recycling tips

Our top recommendations on packaging series continues with ideas on reusing your cardboard boxes and corrugated cartons - there're 3 reasons to reuse your cardboard boxes and packaging cartons.

As pressure for the environment and the require for the nation to economise grows, it becomes critical to protect and reuse packaging, Reusing packaging is the greatest form of recycling, simply because it doesn't require further use of energy, either in converting or transporting the packaging according touse. It simply extends the life using the cardboard boxes.

Thinking ahead to how your customer receives their delivery, reducing unnecessary packaging and which makes it easy for the individual to reuse their cartons and boxes, or other corrugated packaging, could have a positive impact on your environmental credentials as a specialist packaging design company we believewe now have a duty to encourage customers to give greater considered to the packaging they purchase and produce better use of the packaging materials they retain.

How to reuse your cardboard boxes other than buying new cartons

Plain brown boxes are easier to recycle than custom printed cardboard boxes. So in the case companies could use these with removable labels instead of ordering specially printed cartons, the life of the box will be extended.When you or your staff accepts deliveries, open cardboard boxes carefully, cutting along any packaging tape. Don't pull open the top, simply because this can cause the carton to tear or weaken.

Avoid cutting or scoring the cardboard, since this will weaken the box when empty, store boxes flat. This not only saves space, but avoids unnecessary usage or crushing. To flatten a box, simply cut following the taped join at the bottom and fold flat. Your box will be held in good shape until it is ready for reuse cardboard boxes come inall designs, so that they can reuse, you'll probably need void fill or other packaging to pack within the item. We suggest reusing bubble wrap, paper from the office shredder or other recycled packaging.

Never write directly onto a cardboard box. Use an address label or documents enclosed label that could be easily covered or removed through the next user. When assembling cardboard boxes, use packaging tape in place of staples where possible. Simply because corrugated cardboard can rip when staples are removed. If you need to send a heavy item, use a durable cardboard box or export carton.

Finally, make sure to stack boxes neatly, use corrugated cardboard sheets between layers on a pallet instead ofover-stack. Everyone knows you can avoid edge crushing which weakens the box. When your cardboard boxes have reached the endof their usable life, they may be shredded and used as loosefill packaging, or recycled. Most corrugated cartons are made from 100% corrugated kraft board and are therefore worthwhile for recycling schemes.

Thursday, July 28, 2011

Corrugated box design rules for export business purpose

The outer packaging would not meet local regulations reasons for frequent business return of Chinese products. In the output of export corrugated paper box of companies, needs to have aroused a high degree of attention. When it comes to corrugated carton it must be noted inside the design with the details.

Shape Design Tips to Note1. Export carton box in the look, we need toconsider thetransit bumps, abrasions, wear, fall, handling as well as other external shocks force. Therefore, as large packaging, corrugated boxes as far as possible during thedesign simple, simple to transport, in order to avoid cutting, die-cutting process for utilizing an excessive amount will slow up the effectiveness of cartons, but seems to make process too complicated. At the same time, also consider packing convenience, and many mechanical packing, etc. ought to beconsidered.

2. Inside the design of corrugated box sizes, we have to consider and integrate different container types, take advantage of container space, avoiding the item in transit there surplus space, awaste material within the transport process does not help security in. Besides, the corrugated box of length, width and height ratio also for the contents.

3. In accordance with the local transportation, handling the situation, may be included in handle the larger box holes so simple to use design, which would facilitate handling. Material Selection Tips to NoteThe strength of corrugated box design, materials and design,is an essentialpart, it not just affects print effect, but in addition affects the corrugated shape considering that the physical properties. 1. Strength corrugated paper between water content as well as a close relationship. In the corrugated box with paper, think about the climate conditions of numerous countries, as for instance, when the weather can often dry paper as raw material; the climate is wet, or need frozen the corrugated box can be performed with waterproof paper, raw materials, so as to ensure that the physical properties of corrugated containers from air and humidity change. We're able to use SN/T0262-93 standards of the three sorts of different factors to decide paper deterioration within the situation, the general store of a shorter corrugated box can be less quantitative and gratification of paper, otherwise high. As a manufacturer, can act in line with circumstances produce marketable products. 2. The declareis only included in the domestic corrugated box (GB6543) and exports of corrugated boxes (GB/T5033) set the standard respectively. Export corrugated several of the indicators have improved, so we assigned paper, using the raw material of paper have to have a bigger physical properties, just like ring crush index. Also pulled out cardboard should also burst, side compression, adhesion and various physical performance requirements to meet the GB5034. 3. Ink, adhesives and varnishes (coated) and choose the destination country's rules must be deemed in this regardreally need to be considered is an environmental protection requirements. Such as, the printing ink might choose now internationally popular vegetable oil-based ink, it hasminimal body damage. Now a major portion of many countries with flexible packaging printing as the main approach to use flexible printing without Solvent Of UV inks And Water-based ink Can minimize the harm, no pollution.

In short, as much as possible to go for pollution-free materials avoiding packaging problems return, especially exports in the EU's product packaging is particularly noteworthy. Internal design attention to points 1. Box in the sign should be. GB191 provision needs to be printed in carton commodity Inspection Department under the code and code, especially the box on the lot,is the focus of thorough investigation of the commodity inspection authorities, but also simple to leave out the point that numerous companies, be sure the batch number box. Box surface design, text clear and accurate, consistent depth, plus the correct position. At the moment, some products has to be printed on the mandatory sign. At design time, giving thought to updating the existing standards, by using the latest standards. 2. Box within the reference standards (international standards, inspection standards, national standards) code demands the latest standards. To the customer is responsible, manufacturers need to constantly update and enrich the knowledge. The box pattern, should be depending on national cultural differences may be, cannot stick to the traditional practice in our country, design is simple, single color is preferred. The folks of every country has different preferences, there are numerous taboos, the moment within the internal design is in particular noteworthy.

Process Design Key Points to note corrugated box forming process there are various intermediate links in the design of our noteworthy.1. Corrugated design mainly the design of corrugation. Contents before in accordance with the characteristics of the transport environment and the utilization of materials and needs of strength to the design of corrugation. There are severalsingle corrugated and multi-layer corrugated, each floor there are A, B, C, etc. as needed to select (the national standard is not described in detail here). 2. Print design. There are many printing, corrugated box frequently used in Chinai n the primary strategies to offset printing, flexo printing, gravure printing, etc.. Printing directly affect shift in the way of other craft, or possibly printed material have changed. For instance, select coating sheet board paper, water color ink printing flexo printing is very difficult. Can offset, flexo and gravure printing its own characteristics and comprehensive consideration of other facets of the design process plan.

In summary, the export of corrugated box design includes several aspects mentioned above, each of them is not isolated, but alternatively influence each other. In each respect, only thoughtful, it doesn't make corrugated boxes become the bottleneck of exports.

Shape Design Tips to Note1. Export carton box in the look, we need toconsider thetransit bumps, abrasions, wear, fall, handling as well as other external shocks force. Therefore, as large packaging, corrugated boxes as far as possible during thedesign simple, simple to transport, in order to avoid cutting, die-cutting process for utilizing an excessive amount will slow up the effectiveness of cartons, but seems to make process too complicated. At the same time, also consider packing convenience, and many mechanical packing, etc. ought to beconsidered.

2. Inside the design of corrugated box sizes, we have to consider and integrate different container types, take advantage of container space, avoiding the item in transit there surplus space, awaste material within the transport process does not help security in. Besides, the corrugated box of length, width and height ratio also for the contents.

3. In accordance with the local transportation, handling the situation, may be included in handle the larger box holes so simple to use design, which would facilitate handling. Material Selection Tips to NoteThe strength of corrugated box design, materials and design,is an essentialpart, it not just affects print effect, but in addition affects the corrugated shape considering that the physical properties. 1. Strength corrugated paper between water content as well as a close relationship. In the corrugated box with paper, think about the climate conditions of numerous countries, as for instance, when the weather can often dry paper as raw material; the climate is wet, or need frozen the corrugated box can be performed with waterproof paper, raw materials, so as to ensure that the physical properties of corrugated containers from air and humidity change. We're able to use SN/T0262-93 standards of the three sorts of different factors to decide paper deterioration within the situation, the general store of a shorter corrugated box can be less quantitative and gratification of paper, otherwise high. As a manufacturer, can act in line with circumstances produce marketable products. 2. The declareis only included in the domestic corrugated box (GB6543) and exports of corrugated boxes (GB/T5033) set the standard respectively. Export corrugated several of the indicators have improved, so we assigned paper, using the raw material of paper have to have a bigger physical properties, just like ring crush index. Also pulled out cardboard should also burst, side compression, adhesion and various physical performance requirements to meet the GB5034. 3. Ink, adhesives and varnishes (coated) and choose the destination country's rules must be deemed in this regardreally need to be considered is an environmental protection requirements. Such as, the printing ink might choose now internationally popular vegetable oil-based ink, it hasminimal body damage. Now a major portion of many countries with flexible packaging printing as the main approach to use flexible printing without Solvent Of UV inks And Water-based ink Can minimize the harm, no pollution.

In short, as much as possible to go for pollution-free materials avoiding packaging problems return, especially exports in the EU's product packaging is particularly noteworthy. Internal design attention to points 1. Box in the sign should be. GB191 provision needs to be printed in carton commodity Inspection Department under the code and code, especially the box on the lot,is the focus of thorough investigation of the commodity inspection authorities, but also simple to leave out the point that numerous companies, be sure the batch number box. Box surface design, text clear and accurate, consistent depth, plus the correct position. At the moment, some products has to be printed on the mandatory sign. At design time, giving thought to updating the existing standards, by using the latest standards. 2. Box within the reference standards (international standards, inspection standards, national standards) code demands the latest standards. To the customer is responsible, manufacturers need to constantly update and enrich the knowledge. The box pattern, should be depending on national cultural differences may be, cannot stick to the traditional practice in our country, design is simple, single color is preferred. The folks of every country has different preferences, there are numerous taboos, the moment within the internal design is in particular noteworthy.

Process Design Key Points to note corrugated box forming process there are various intermediate links in the design of our noteworthy.1. Corrugated design mainly the design of corrugation. Contents before in accordance with the characteristics of the transport environment and the utilization of materials and needs of strength to the design of corrugation. There are severalsingle corrugated and multi-layer corrugated, each floor there are A, B, C, etc. as needed to select (the national standard is not described in detail here). 2. Print design. There are many printing, corrugated box frequently used in Chinai n the primary strategies to offset printing, flexo printing, gravure printing, etc.. Printing directly affect shift in the way of other craft, or possibly printed material have changed. For instance, select coating sheet board paper, water color ink printing flexo printing is very difficult. Can offset, flexo and gravure printing its own characteristics and comprehensive consideration of other facets of the design process plan.

In summary, the export of corrugated box design includes several aspects mentioned above, each of them is not isolated, but alternatively influence each other. In each respect, only thoughtful, it doesn't make corrugated boxes become the bottleneck of exports.

Wednesday, July 27, 2011

The adantage of corrugated box and the design service you can get

If you're thinking of avail cardboard boxes on yourarduous packaging stuffs, Corrugated cardboard is the best option available. In case you are now thinking that what this corrugated cardboard is focused, the truth is, it is nothing distinct from a cardboard, moreover it is easily obtainable in single, double and triple walls. So now you don't need to concern yourself with the damaging in the precious stuffs when you are heading towards long journey because corrugated cardboard boxes make sure you about their safety. A number of its benefits are listed below:

Cost-efficient- Given that the corrugated cardboard is renewable in the wild, it is usually provided at minimal cost.

Safety-As there aren't any sharp edges or secedes, you can certainly carry and it is safe.

Environmental friendly- As the boxes are produced from recycled materials, they are renewable and therefore can be utilised continually.

Easy printing: The box lets you to mark your company names, logos etc easily, as other material hardly allow.

Completely durable: The boxes were created with material that includes along lasting guarantee.

The Corrugated cardboard also referred as brown boxes, it is not made with any ordinary cardboard; rather it holds three complex layers of cardboard that are called outer liner, which is the exterior of the box, inner liner which is a hardcore and prevents the box from heavy damage. Then final layer is the Fluting medium that maintains the entire reliability of the box, it can retain extreme heat and pressure. You ought to be thinking which material is utilized for producing these boxes, well staple material for constructing these boxes is pine tress, and the companies manufacturing these boxes probably have their very own land in which these trees are grown. Moreover there are chemicals involved in the procedure for their manufacturing, a fibrous pulp is made, and this pulp is employed for manufacturing large rolls of Kraft papers through a process. However corrugated boxes are manufacturedby the entire recycling, which involves breaking of the box and technique is same as making corrugated box from scratch.

Packmage, a brand name that offers corrugated cardboard boxes design services worldwide. They shoot for an extensive improved packaging design that offers the customers best service, company expert team design every type of boxes that serve the client using a best possible way, you should have adetailed view of the services at www.packmage.com.

Cost-efficient- Given that the corrugated cardboard is renewable in the wild, it is usually provided at minimal cost.

Safety-As there aren't any sharp edges or secedes, you can certainly carry and it is safe.

Environmental friendly- As the boxes are produced from recycled materials, they are renewable and therefore can be utilised continually.

Easy printing: The box lets you to mark your company names, logos etc easily, as other material hardly allow.

Completely durable: The boxes were created with material that includes along lasting guarantee.

The Corrugated cardboard also referred as brown boxes, it is not made with any ordinary cardboard; rather it holds three complex layers of cardboard that are called outer liner, which is the exterior of the box, inner liner which is a hardcore and prevents the box from heavy damage. Then final layer is the Fluting medium that maintains the entire reliability of the box, it can retain extreme heat and pressure. You ought to be thinking which material is utilized for producing these boxes, well staple material for constructing these boxes is pine tress, and the companies manufacturing these boxes probably have their very own land in which these trees are grown. Moreover there are chemicals involved in the procedure for their manufacturing, a fibrous pulp is made, and this pulp is employed for manufacturing large rolls of Kraft papers through a process. However corrugated boxes are manufacturedby the entire recycling, which involves breaking of the box and technique is same as making corrugated box from scratch.

Packmage, a brand name that offers corrugated cardboard boxes design services worldwide. They shoot for an extensive improved packaging design that offers the customers best service, company expert team design every type of boxes that serve the client using a best possible way, you should have adetailed view of the services at www.packmage.com.

Friday, July 22, 2011

Knowledges about carton box you need to know for your online business

Once you start your business trading online, you must take a look by parcels how to dispatch your products or services to your own consumer. The main options are cardboard boxes and bags. Bags are super easy to pick with size, colour and thickness and they are good for small-scale products however when you beginning of send much bigger items you have got to take a look by cardboard boxes. These kinds of contain a much bigger alternatives and then here I will aim to reveal a tiny bit about the theifs to provide help to select an experienced cardboard boxes to help deliver marketing on.

The question is that it is possible to Abroad Particle board Scenario Computer code? The latest Code developed by FEFCO along with ESBO (American Strong Block Organisation) for endorsed system to assist you to exchange extended along with intricate mental sorts of fibreboard case and additionally packaging buildings utilizing effortless significance worldwide perceived as a result of many, despite of vocabulary besides other distinctions. This FEFCO-ESBO policy is undoubtedly acquired by means of ICCA, this Unusual Corrugated Circumstance Correlation, having globally members.

Are there any difference between the words carton and box? No matter whether you apply the the word carton or maybe box often does not make a difference while they simultaneously identify the same thing. Box is usually widely used even more than carton with Customers, unlike all the packaging and even linked business frequently take advantage of carton. Any period you'd rather take advantage of, we'll find out what you will be dealing with. That which is corrugated board? Corrugated board incorporates not one but two report components: typically the choice along with the linerboard. That channel is often a fluted corrugated bed sheet that is certainly sandwiched relating to not one but two documents regarding linerboard dealing with some. Both of them are made of poster board (generically categorised as "composition board") the industry pieces of paper-like substance sometimes made from 2 or more plies to give you the mandatory stiffness.

It is possible to difference between single wall and double wall corrugated cardboard? Single wall corrugated cardboard includes a single fluted methods among several documents about linerboard. Double wall corrugated cardboard as its identity suggests, carries a few fluted channels sandwiched approximately a few sheets about linerboard.

As a result with a little luck now you can create an informed selection about what is right for you , good luck with your online business.

The question is that it is possible to Abroad Particle board Scenario Computer code? The latest Code developed by FEFCO along with ESBO (American Strong Block Organisation) for endorsed system to assist you to exchange extended along with intricate mental sorts of fibreboard case and additionally packaging buildings utilizing effortless significance worldwide perceived as a result of many, despite of vocabulary besides other distinctions. This FEFCO-ESBO policy is undoubtedly acquired by means of ICCA, this Unusual Corrugated Circumstance Correlation, having globally members.

Are there any difference between the words carton and box? No matter whether you apply the the word carton or maybe box often does not make a difference while they simultaneously identify the same thing. Box is usually widely used even more than carton with Customers, unlike all the packaging and even linked business frequently take advantage of carton. Any period you'd rather take advantage of, we'll find out what you will be dealing with. That which is corrugated board? Corrugated board incorporates not one but two report components: typically the choice along with the linerboard. That channel is often a fluted corrugated bed sheet that is certainly sandwiched relating to not one but two documents regarding linerboard dealing with some. Both of them are made of poster board (generically categorised as "composition board") the industry pieces of paper-like substance sometimes made from 2 or more plies to give you the mandatory stiffness.

It is possible to difference between single wall and double wall corrugated cardboard? Single wall corrugated cardboard includes a single fluted methods among several documents about linerboard. Double wall corrugated cardboard as its identity suggests, carries a few fluted channels sandwiched approximately a few sheets about linerboard.

As a result with a little luck now you can create an informed selection about what is right for you , good luck with your online business.

Thursday, July 21, 2011

Box application in packaging industry

Boxes are used intended for any large number regarding purposes, but in the particular industries, they are mostly used regarding packaging. There are different kinds regarding boxes with respect to different kinds involving packaging. The shapes, sizes not to mention this materials belonging to the boxes depend on what they contain.

Boxes are some of this most useful items used for the purpose of packing. They are widely used in all the packaging industry with respect to packing a fabulous big range involving products including bottles, furniture, electronics in addition to mechanical equipment, sports gear and also even art works, among others. They have many classifications such as corrugated box, carton box, wooden box, bulk box etc. They can also be classified on the basis of one's kind associated with purpose they are going to serve e.g. boxes designed for bottles, postal, mugs, picture frames, stationery etc.

Cardboard box is without a doubt very common for the purpose of packaging purposes. There can be four different kinds from cardboard boxes: standard, heavy duty, white with triple wall. The first type might be pertaining to single wall usage not to mention can be made involved with corrugated craft layer. The inner part is recycled flute. They are often packed flat plus this flaps need to help you be taped often. The heavy duty cardboard package was made to reduce typically the overall requirement with regard to packaging, thanks to assist you to its large space, greater strength due that will double layered walls and even 7% lighter materials.

White cardboard boxes can be of standard, postal, cake, solid board in addition to recycle bin types. The triple wall cardboard pack has some sort of layer with craft on a outside and then has recycled flute. They also have corrugated layers. Corrugated boxes themselves are very useful as shipping containers. They often have inner components like blocking, cushioning and bracing regarding fragile contents. Such a new container may often contain labels, bar codes printed on the following not to mention graphical designs. Stacking strength is really a very important parameter meant for boxes. This signifies these resistance to crushing.

Some other classifications in boxes may be made mirror, dish packs, legal tote, book, wardrobe along with mattress boxes. These boxes carry exactly what a names imply not to mention in particular, legal tote boxes are meant with respect to carrying files not to mention folders. Other boxes include those meant for postal or mailing purposes, mugs and even packing electronic goods, which are often fragile.

Tuesday, July 19, 2011

5 steps to master carton box packaging design

In Packaging industry, Packaging design is always the hottest topic, no matter design studio, prototype factory, packaging manufacturer, even packaging machine factory considered about what they need to improve to help client benefiting the packaging design, there’re lots of excellent software for carton box packaging design, such as artioscad, cimpack, autocad etc. Today I would like to introduce a new carton box packaging design software Packmage to help users get their carton box designed in a few steps:

The first step, select box from the library, Packmage carton box packaging design software offers hundreds of boxes in the library and the quantities updated every week.

| ||

| Packmage box library |

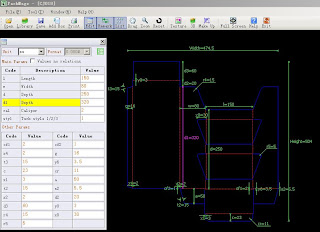

The second step is parametric design, modify the box size according to your requirements.

|

| carton box parametric design |

Here you can modify the parameters in the tablet of the left menu, the box will be adjusted automatically after the parameter value changed, also the user can check the information such as box size, the total length of die-line and folding-line, paper utilization etc.in the parametric design interface.

The Third step is texture, in the texture interface, user can import the graphic design of the box.

| |

| texture with graphic design |

Users can texture the whole box or each individual part of the box according to their requirement, the 4 direction keys can be used for matching the graphic design with the box structural design.

The fourth step is 3D box modeling, with this feature user can check if there’s any flaw with the box structure design during the modeling process.

| ||

| 3D box modeling |

The Packmage 3D interface is very friendly, user can move the mouse to the button to know the feature. With Packmage 3D users can get the 3D box effect with photo or video so that they can show to clients immediately without proofing.

The fifth step is step and repeat, after the box structure design and graphic design finished, Packmage makeup module can offer the best sort solution for box step and repeat.

| ||

| Packmage box step and repeat |

With this module, user can step and repeat one or more boxes in one cardboard in order to save cost, also it offers information like paper utilization rate, the total length of die-line, folding line etc. The final file can be exported as DXF or PDF format.

Isn't it easy for carton box design? If you still confused about how to design a carton box you can check Packmage video introduction directly.

Monday, June 27, 2011

Packmage carton box design software box templates

|

| Semi-Auto Lock carton box dieline templates |

|

| Dispensers_Displays carton box dieline templates |

|

| Promotions_Gifts carton box dieline templates |

|

| Crash Lock Buttom carton box dieline templates |

|

| Tuck End carton box dieline templates |

Monday, May 30, 2011

Dieline in Packmage carton box design

What is a Dieline?

The dieline is the template for a package. It’s a flattened outline of the cutlines and folds. You cannot create a product package design without one – so don’t even try.If you took apart a cereal box and flattened it out, you’d be looking at the dieline. The edges of the box are the cutlines and all the seams and creases are the folds and overlaps. It’s basically supermarket origami that must also be sturdy, functional and do a darn good job of attracting the consumer’s interest.

Your dieline must be perfect. You’ll be creating an extremely tight layout, a pixel perfect balancing act between competing design elements, so even loosing an eighth of an inch will often require a reworking of the entire package. This is why I never start a package design without a finalized dieline. Otherwise I’m just guessing and ultimately wasting my time and giving my client a false sense of accomplishment.

So How Do You Create a Dieline?

If you get a finalized dieline straight from the printer (the most likely scenario), it will have the bleed requirements and all the manufacturing notes already on it. This is ideal and if you have that you don’t need this tutorial.However, sometimes you’ll be working with a client in the early stages. Perhaps they’ll send you a box from another product and direct you to make one just like it. Maybe they’ll FedEx you a bottle or jar and ask you to make a label that maximizes the container’s real estate. Or maybe they’ll send you the product itself and ask you to design a box, clamshell or blister pack to hold it. If this is the case then this tutorial is for you.

Labels and other two dimensional package designs are easy and you can generate perfect dielines for these on your own. However, unless you are reproducing an existing box, working from an existing dieline, or you have extensive experience in CAD applications, you can’t realistically create a perfect three dimensional package dieline on your own. However, you can start the ball rolling and then turn over your dielines, notes, and a sample of the product to a printer or manufacturer and they can use it as the basis for creating a working dieline.

Dieline in Packmage

For begginers, packmage predefined dieline in the box struture, you can check the photoes as follow:http://packmage.blog.com/files/2011/05/ZW001-buttomlocktray.jpg

Since Packmage predefined dielines and box shapes, it’s much more convenient for new user.

Packmage 3D box modeling new improvements

Packmage 3D box modeling features new improvements will be released soon, there are the details:

1> Solved the 3D high definition compatibility with 64-bits OS systems;

2>3D lights intensity and angles can be adjusted with nice presentation;

3>3D cardboard inside background color has been modified;

4>paperboard of hollow out clipping in 3D presentation improved.

1> Solved the 3D high definition compatibility with 64-bits OS systems;

2>3D lights intensity and angles can be adjusted with nice presentation;

3>3D cardboard inside background color has been modified;

4>paperboard of hollow out clipping in 3D presentation improved.

Subscribe to:

Comments (Atom)